|

|

|

|

|

|

| |

|

|

| |

SMD REWORK: - Advanced Rework - FINEPLACER® jumbo rs |

|

| |

|

|

| |

Advanced Rework: - |

|

|

|

|

| |

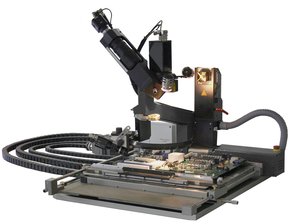

FINEPLACER® jumbo rs

Large Area Rework Station

The FINEPLACER® jumbo rs is a hot air rework station dedicated to handling medium to large sized boards and SMD components with high heat absorption.

Capable of handling the smallest components with pitch down to 200 micron to large BGA components, utilizing a large field of view.

The open system architecture system allows performance of the complete rework cycle within one platform.

|

|

| |

| |

|

Highlights: - |

|

|

- Components from 0.5 mm x 0.5 mm to 90 mm x 140 mm*

- Board sizes up to 750 mm x 500 mm*

- 4 zone segment board heater with flexible board holder*

- Automated top heater calibration

- Closed loop force control*

- Placement accuracy better than 15 µm

|

| |

|

|

| Features |

|

Benefits |

- Automated processes

- Overlay vision alignment system with fixed beam splitter

- Integrated process management (IPM)

- Real time process observation

- System to system process reproducibility

- Adaptive process library

|

|

- Hands-off component placement, user independent process operation

- Outstanding placement accuracy without adjustments

- Synchronized control of all process related parameters: force, temperature, time, flow, power, process environment and illumination

- Immediate visual feedback reduces process development time

- Direct process transfer from development to production saves time and guarantees reliable results anywhere

- Process library allows fast and easy process development for perfectly tailored soldering profiles

|

| |

|

|

| Technologies |

|

Applications |

|

|

- Soldering of:

- BGA, Super BGA, µBGA/CSP, QFN, DFN, PoP, QFP, PGA, SON

- Small passives down to 0603

- RF shields, RF frames

- Connectors, sockets

- Sub assemblies, daughter boards

- Flipchip (C4)

- Pin in Paste (PiP)

- Trough Hole Reflow (THR)

- Reworkable underfill, conformal coating

|

| |

|

|

| Technical Specifications |

|

|

| Placement accuracy*: |

|

15 µm |

| Field of view (min)1: |

|

13 mm x 9.5 mm |

| Field of view (max)1: |

|

83 mm x 62 mm |

| Component size (min)1: |

|

0.5 mm x 0.5 mm |

| Component size (max)1: |

|

80 mm x 80 mm |

| Thermocouples: |

|

2-8 |

| Top Heating: |

|

|

| Power: |

|

900 W |

| Temperature ramp rate: |

|

1 K/s - 50 K/s |

| Flow range: |

|

10 Nl/min - 70 Nl/min |

| Board Heating: |

|

|

| Power: |

|

2100 W |

| Heated area (max)˛: |

|

380 mm x 285 mm |

| Flow range: |

|

96 Nl/min |

| |

|

|

| Modules & Options |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* depending on configuration/application

1 standard value, other values on request

2 optional module

|

|

| |

|

|

|

|

|

| |

|

|

|

|